While there is no question that lithium-ion battery chemistry is a top priority in the wide range of electronics, growing concerns about cost, safety, and production cast doubts about the future of the technology. Sodium ion (Na ion) chemistry is nothing new by comparison, but has crept into recent talks as an alternative to Li-ion batteries.

Recent research developments (such as that to increase sodium storage behavior with electron-rich, element-doped amorphous carbon) aim to make Na-ion batteries a more affordable and sustainable replacement for Li-ion batteries.

Advantages and disadvantages of lithium-ion

Because lithium-ion (Li-ion) chemistry has unmatched electropositivity (or ability to generate energy) and charge density, it is extremely popular as the foundation for batteries in today’s devices ranging from personal electronics to electric vehicles for automobiles become. This means that manufacturers can produce more powerful batteries and keep the packaging relatively compact.

During charging and discharging, lithium ions move back and forth between the two electrodes in a Li-ion battery. Image courtesy of AZo Materials

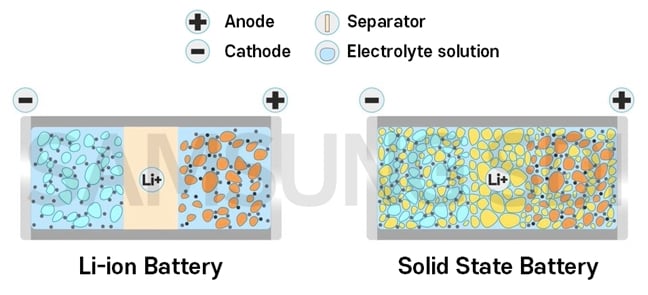

Main batteries – those that are filled with liquid electrolyte solution between the cathode and anode – require a porous barrier to limit chemical activity. Changes in temperature cause this fluid to expand, which can put stress on the outer shells and make them more prone to cracks or breakdowns. Extreme heat easily causes a burn, although the vast majority of batteries will never operate under such conditions. In addition, leaks can attack nearby components.

Internal electrolytes are converted into hydrofluoric acid (HF) after contact with ambient moisture. Short-term inhalation of HF is dangerous and often leads to chronic lung disease and even death. This risk is increased in exposed systems as the acid already becomes gaseous at 19 ° C. As a result, EV giants like Tesla are implementing containment systems to combat this.

Fortunately, solid-state batteries are now available. These newer designs are especially safe. No separators are required, which saves space and shrinks the batteries. Solid-state batteries also have a longer lifespan.

Comparison of the structure of Li-ion batteries with solid-state batteries. Image used courtesy of Samsung

However, more research is needed before this expensive type of battery becomes widespread.

Where sodium ions meet lithium ion challenges

With billions of electronic devices turning to lithium-ion technology, concerns about long-term lithium shortages grow. Lithium is the 33rd most abundant element in the earth’s crust.

In addition, large amounts of cobalt – which are directly above lithium in terms of abundance – are required to form electrodes. Four years ago, an MIT study found that cobalt demand could outperform global supply 1.6 times.

60 percent of cobalt resources are in the Democratic Republic of the Congo, where mining is associated with child labor. In addition to these ethical concerns, companies must also decide whether the cost of $ 33,000 per tonne of cobalt is a sustainable solution.

Sodium-ion (Na-Ion) batteries are not a massive departure from lithium-ion variants. The elemental structure of sodium is quite similar to lithium (a Group 1 metal) and therefore materials testing procedures are similar. The manufacturing processes are also comparable.

Scheme of a Na-ion battery cell. Image courtesy of ACS Energy Letters

Sodium is many orders of magnitude more abundant than lithium – in sixth place overall. It is found all over the earth’s crust and can be harvested from the ocean. Since Na-ion batteries do not require cobalt electrodes, they are also much cheaper.

Research makes Na ions an attractive alternative to Li ions

Although Na-ion technology is by no means new, certain chemical and manufacturing challenges have prevented it from being accepted as a Li-ion battery alternative. Researchers from various institutions have tried to overcome these obstacles in the past few months.

Modified carbon anodes

Korean researchers have already developed new Na-ion designs with modified carbon anodes. This has led to thermodynamic advantages and an increase in capacity. Most Na-ion batteries still use graphite as the anode material, which makes them less efficient. This move promises to make up for the technology’s shortcomings. Scientists tried to do the following:

- Promotion of fast electron transport from the electrolyte to the active material via a porous separator

- Make sodium ions more accessible to the active material in larger locations

- Activate the structured co-intercalation (ion insertion) from the surface to the inside

- Maintain short diffusion paths and microstructures

- Increase the number of active positions

Basic diagram of how the researchers wanted to improve the performance of Na-ion batteries with carbon-based anodes. Image courtesy of Korea Maritime and Ocean University

The researchers assume that under these conditions, Na-ion batteries could match or even surpass their cousins.

A sodium oxide cathode alternative to cobalt

Overall, however, sodium ions are larger than lithium ions; Performance improvements are important to remove deficiencies in energy density. Sodium batteries are not (yet) suitable for portable electronics. They are currently better suited for stationary applications.

Fortunately, Skoltech and its research partners have developed a new sodium oxide cathode material. While cobalt is not that important in Na-ion batteries, sodium cobalt oxide (NaCoO2) remains a common cathode material. Reducing this material dependency is helpful.

In addition, these experimental batteries retain their capacity, withstand moisture, and have little voltage drop. This phenomenon often occurs with a longer LiB cycle. However, the researchers found a voltage hysteresis that could impede manganese migration within the battery.

Research could be the key to advancing Na-ion batteries

Na-ion technology is certainly not a fad. The research spurt reflects the need to overcome bottlenecks and deficiencies with existing Li-ion technologies. However, because the portfolio of LiB devices is so diverse, it may take some time to get mainstream.

Sodium ion battery manufactured by researchers from Zhejiang University, Ningbo University, and Dongguan Technical University. Image courtesy of AIP Publishing

The industries that could benefit most from Na-ion batteries are often those that are now relying on Li-ion batteries: namely portable electronics and electric vehicles.

Ironically, the similarities between chemistry and production strategies are a boon to Na ions. Sodium is not a complex foreign material – it is commonplace and its weaknesses are well known. It can only be a matter of time before engineers and scientists solve the practical problems and bring this type of battery to market.